Surface Design

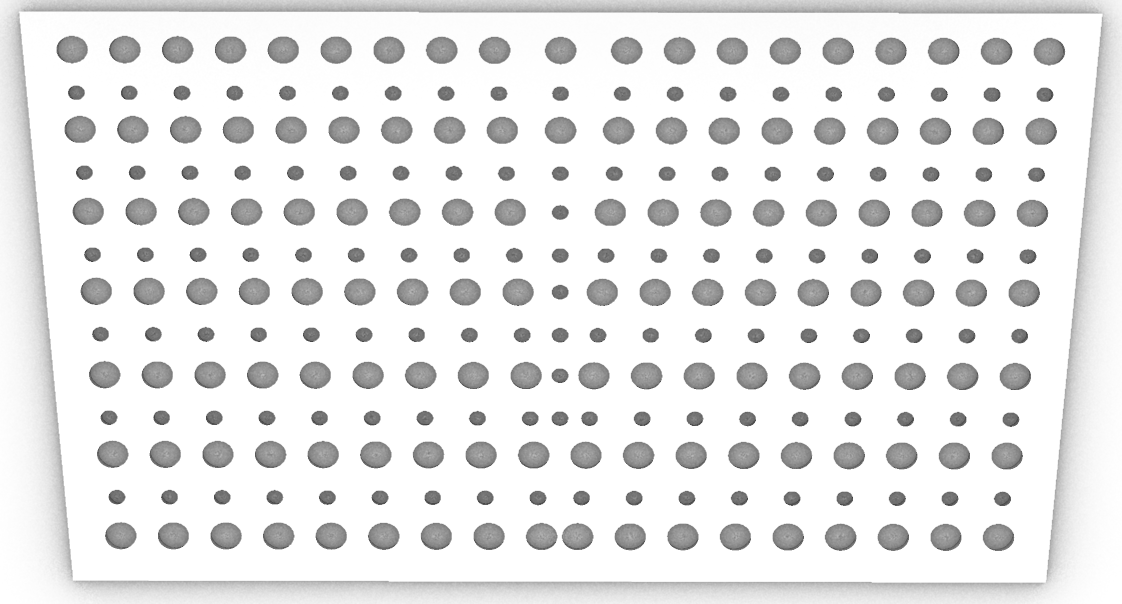

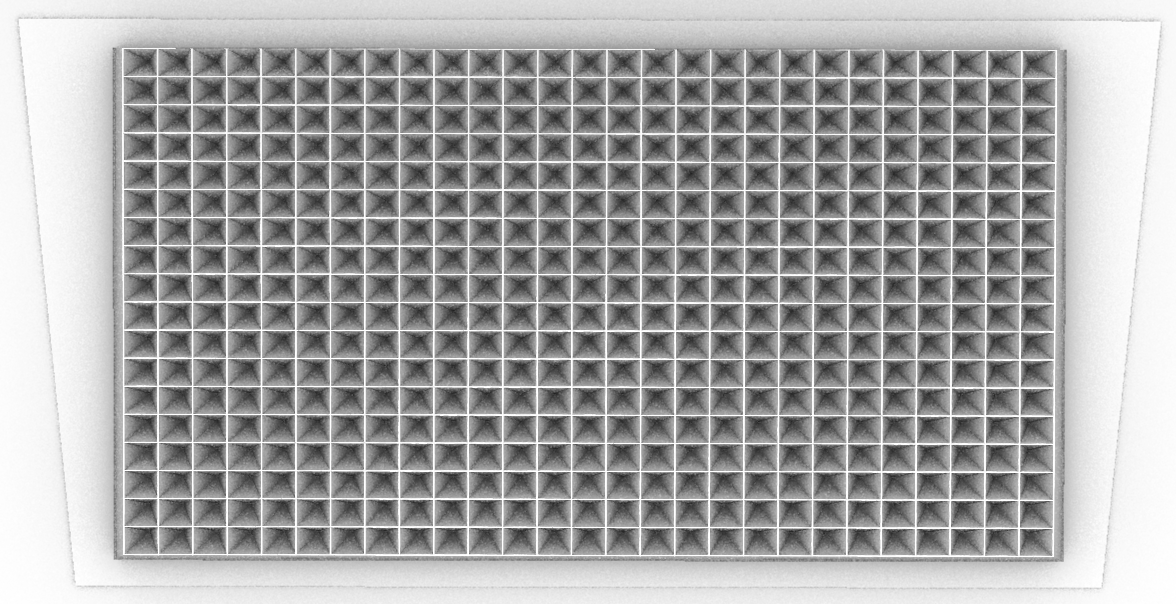

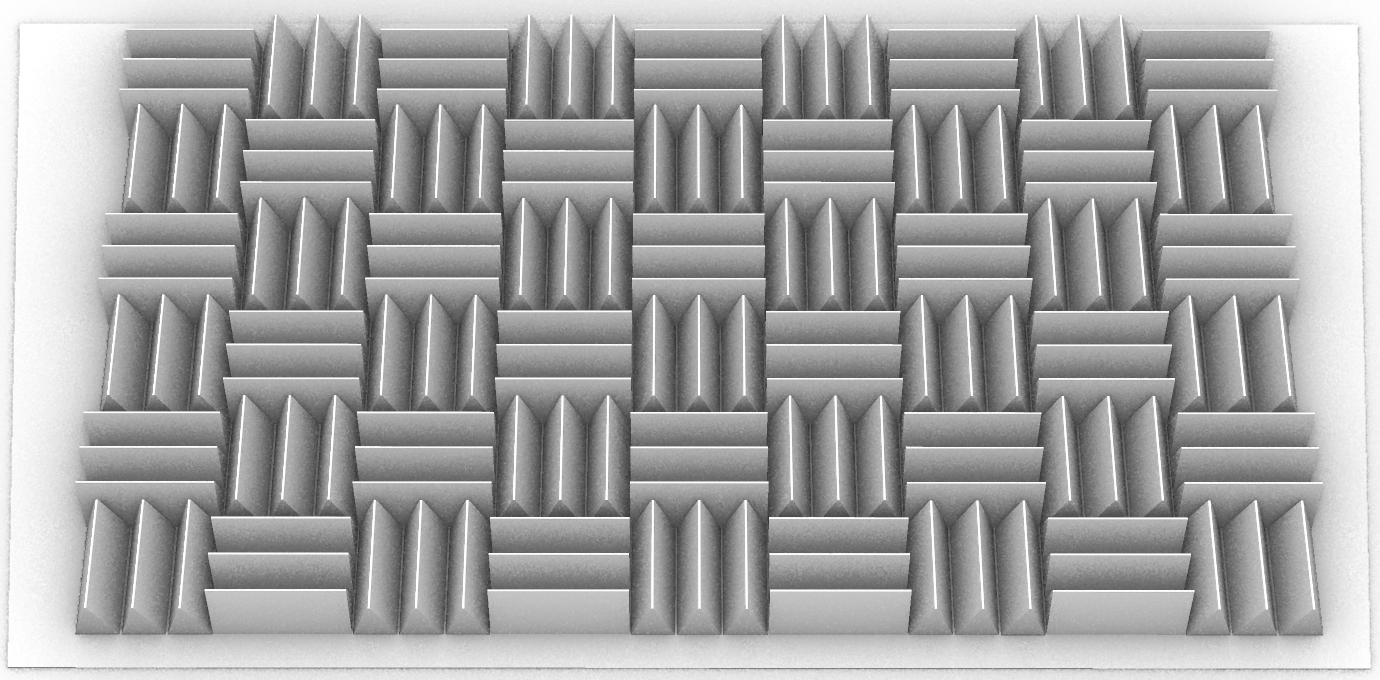

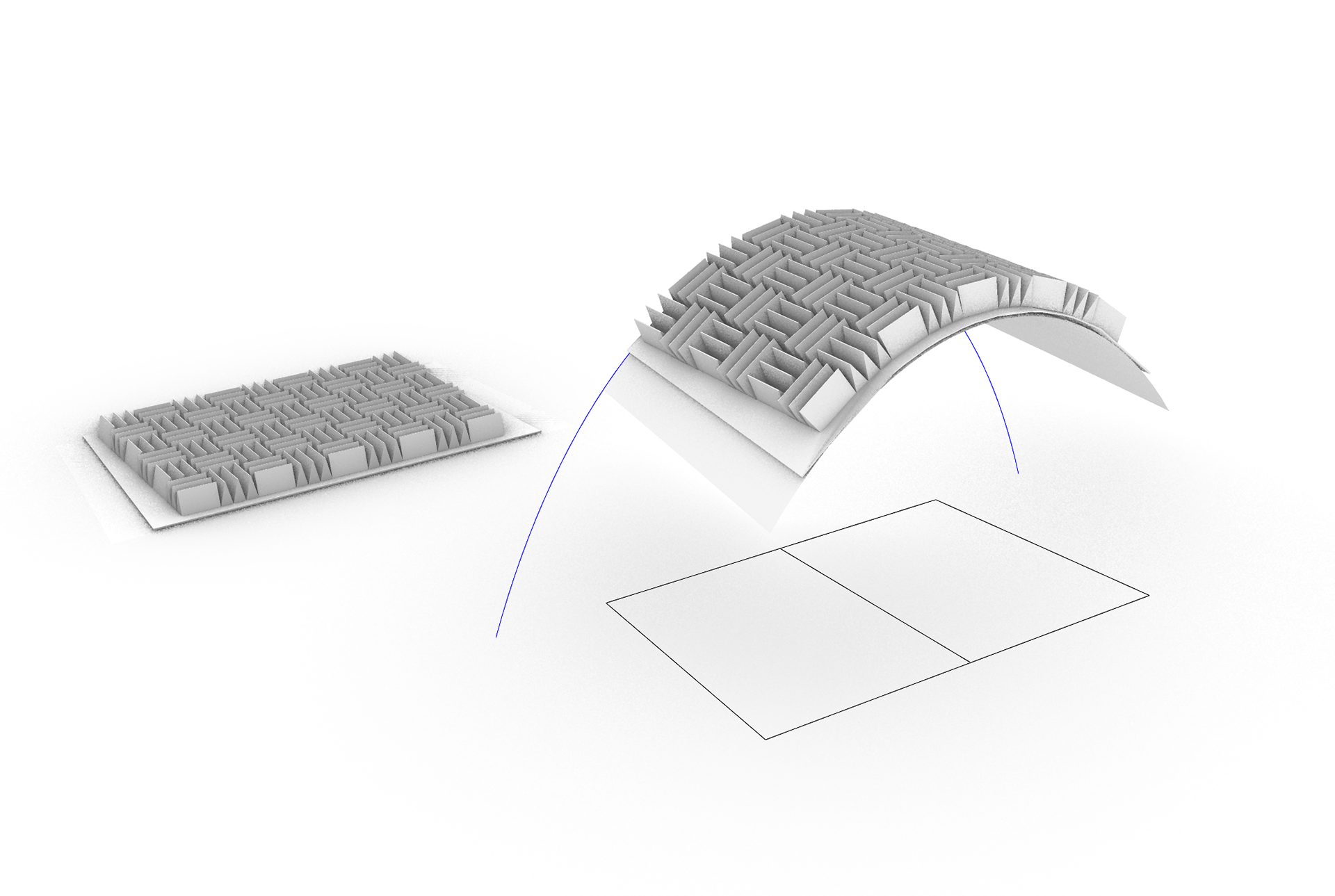

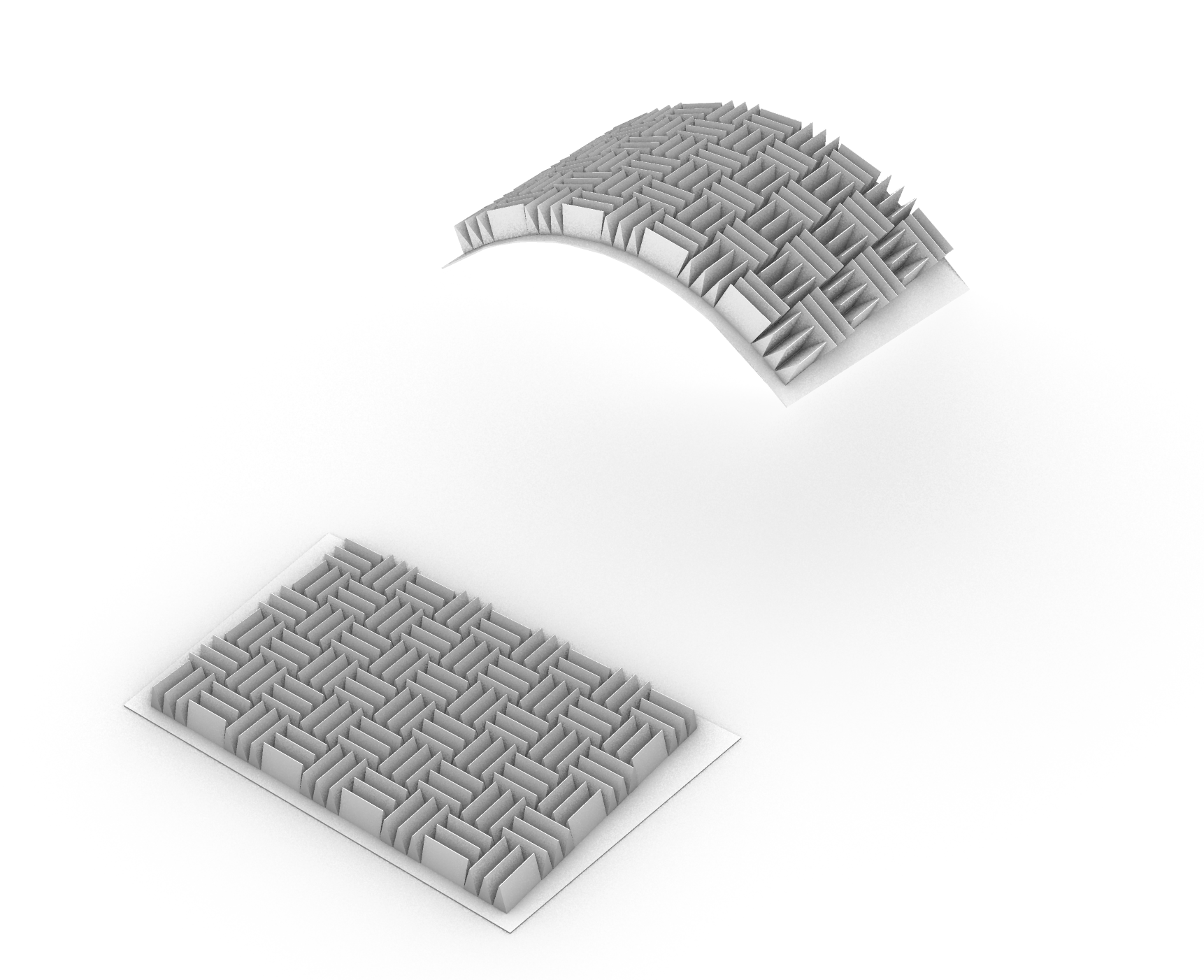

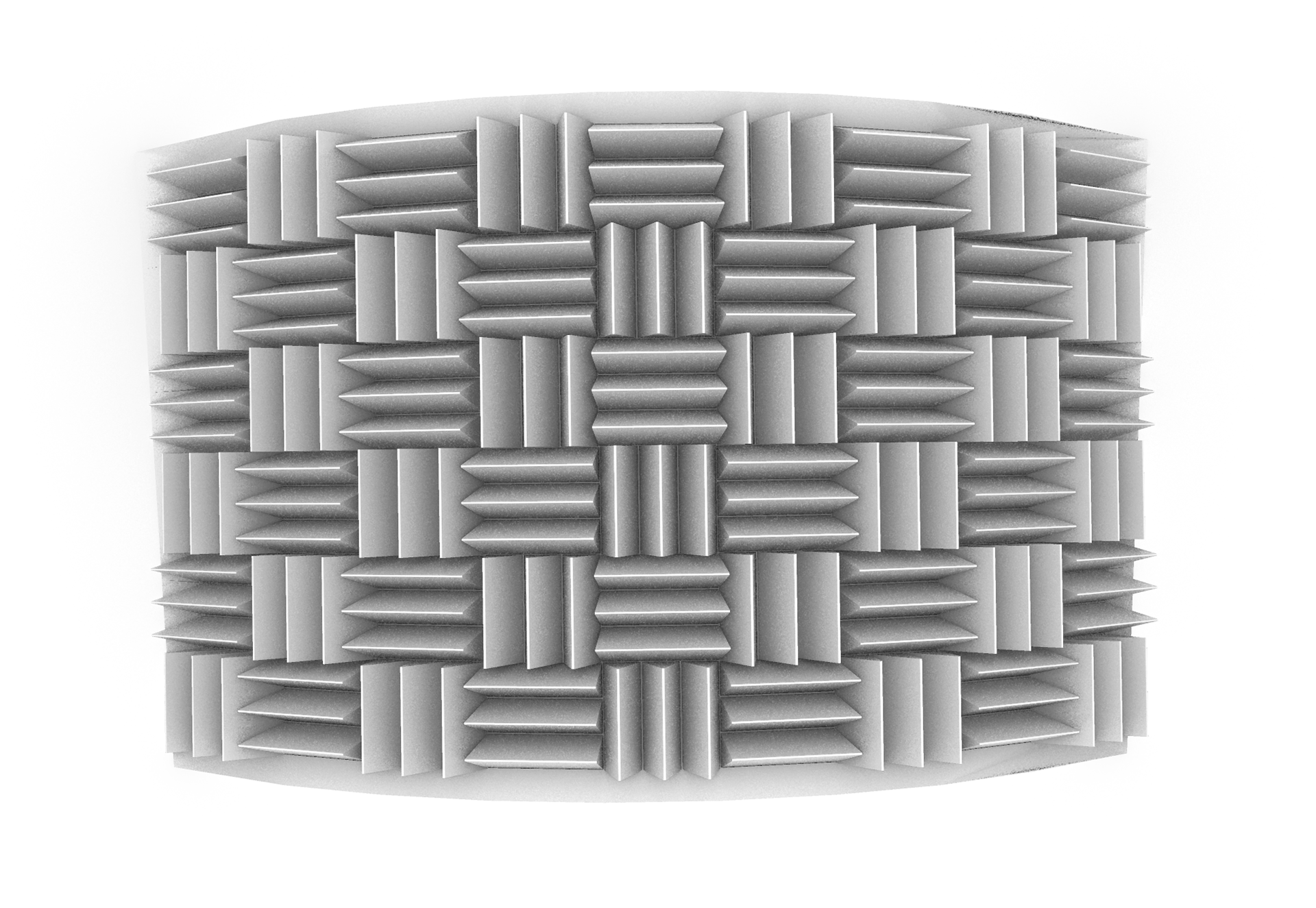

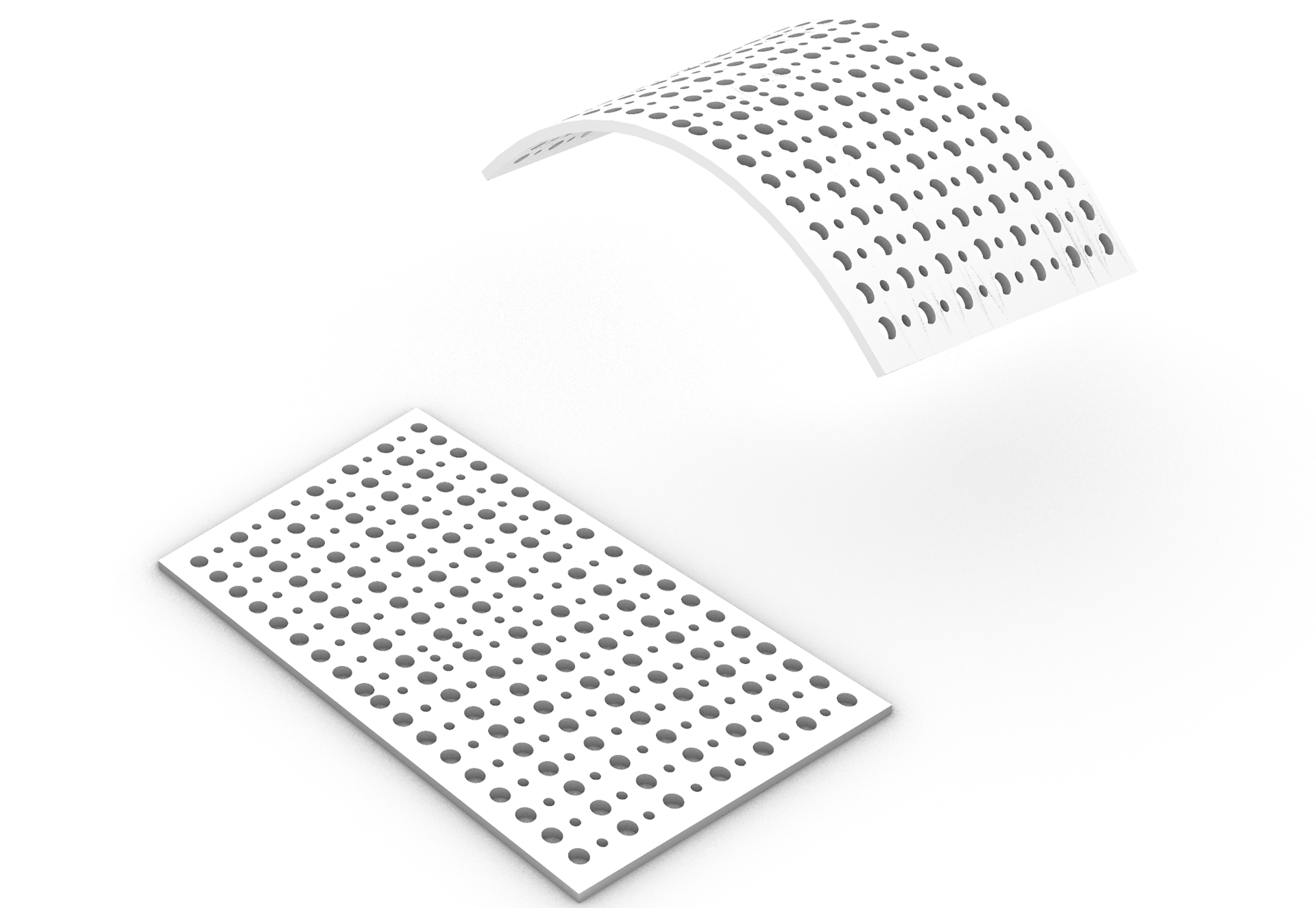

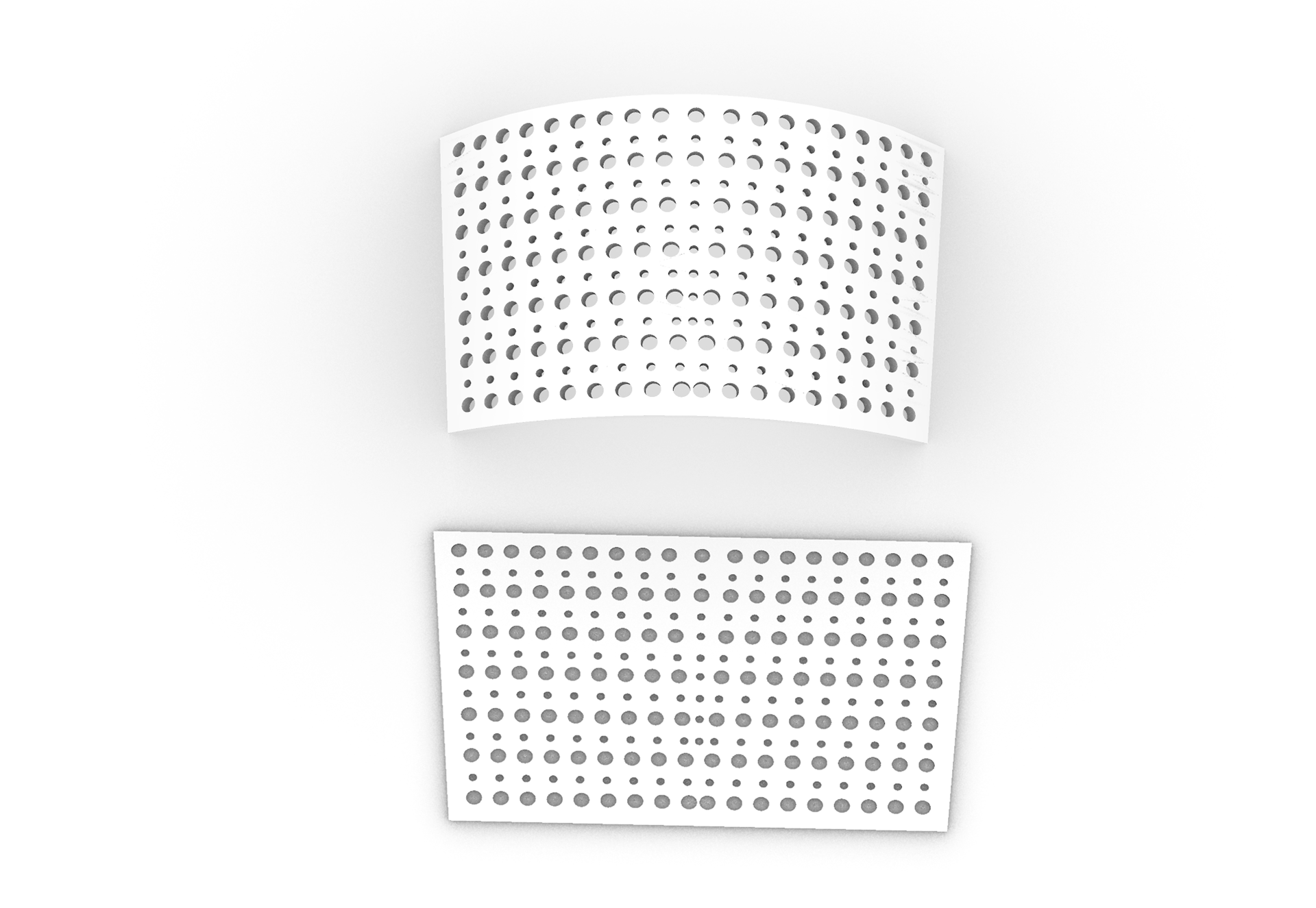

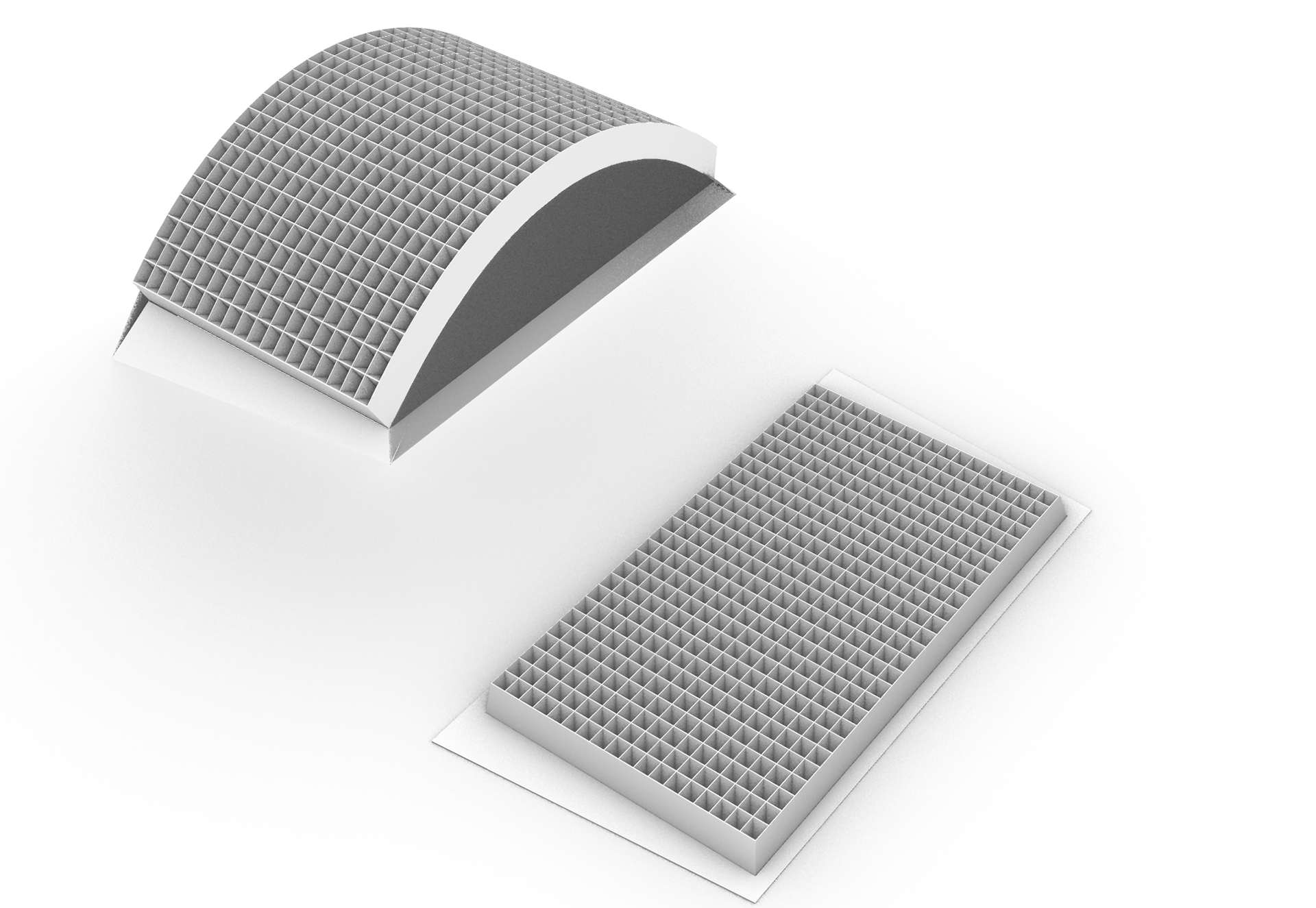

Submarine Tile - Anechoic Grid - Anechoic Patchwork

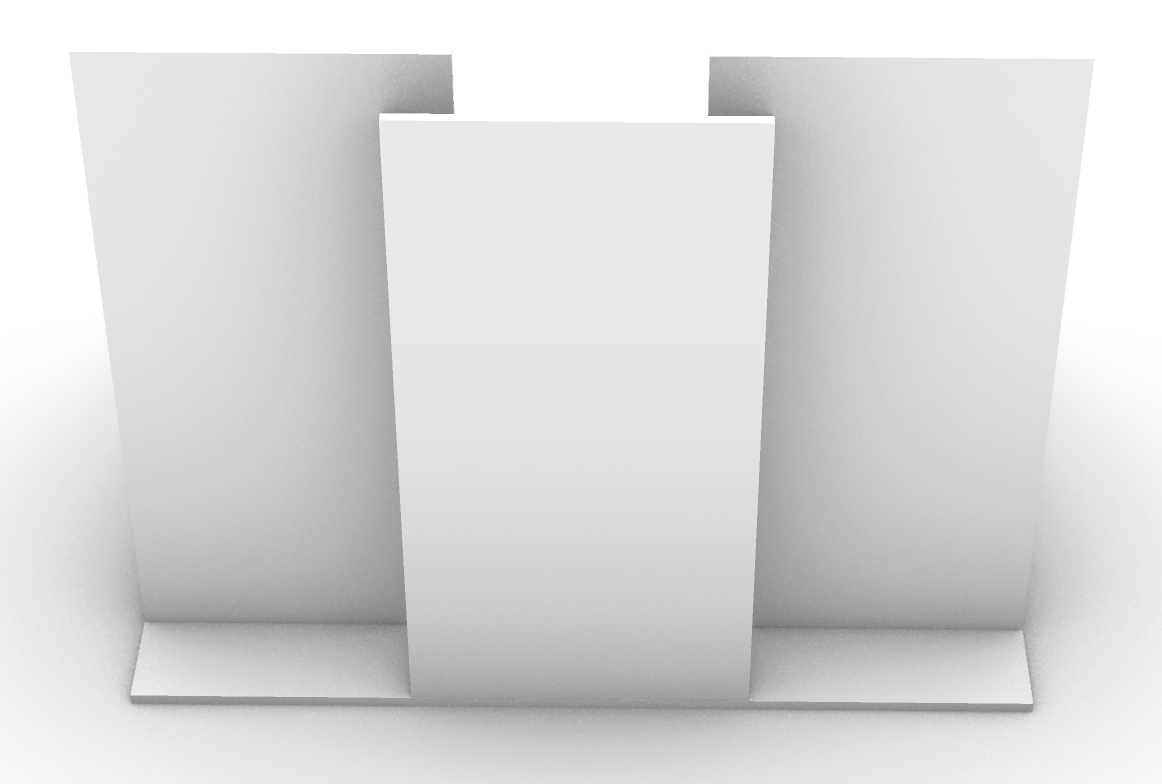

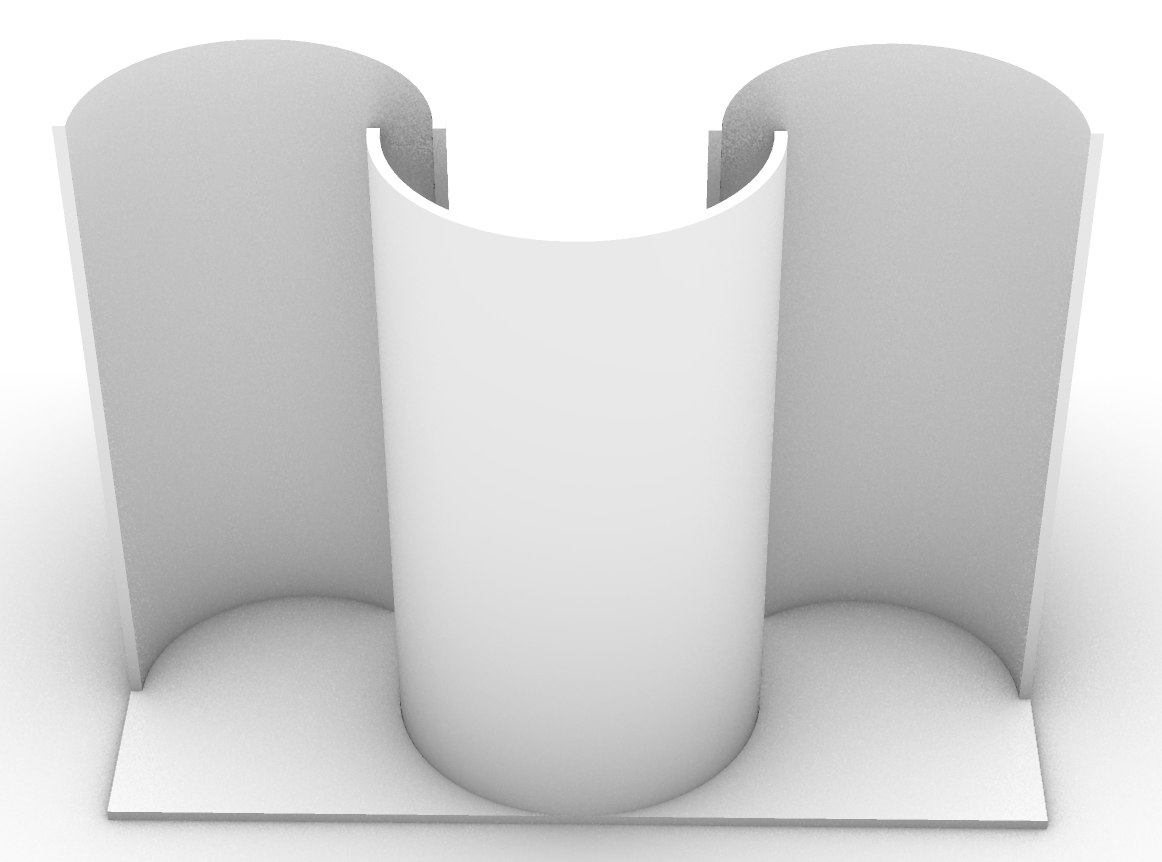

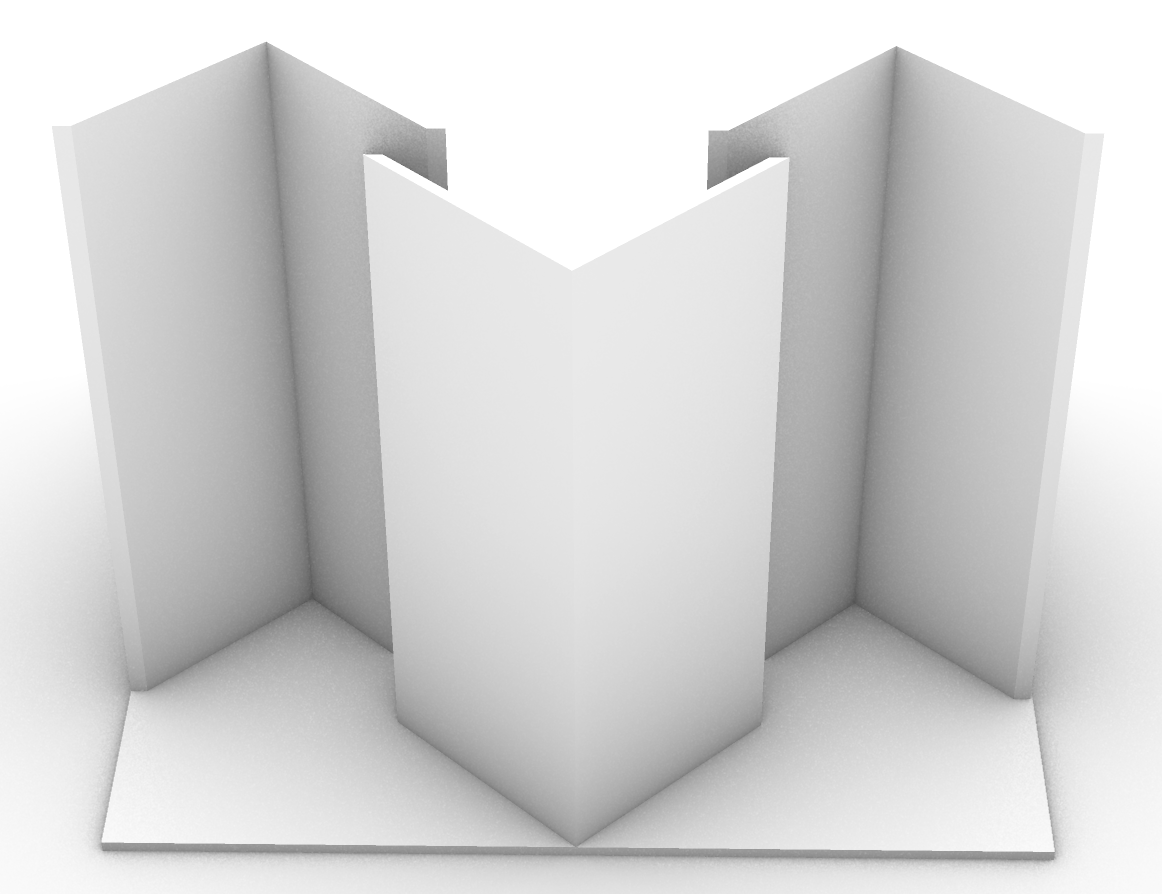

Structural Orientation

Material Exploration

Ceramic

Unglazed ceramic has been used for habitat restoration on coral reefs, providing an inert substrate to colonize which also facilitates the health and growth of the surrounding marine ecosystem.

This proved to be a structurally sound and ecologically friendly material that also added benefit to the environment on top of its applied design. In addition to this, the porous quality of unglazed ceramic also contains sound disrupting qualities in the higher frequency ranges.

All of these factors led to the structural exoskeleton of the design to be made from this material.

Agar Agar

Environmentally friendly material which is effective at absorbing low frequency sound waves. Unlike plastics, rubbers and petroleum based materials Agar does not leach toxic chemicals

Agar is a seaweed bio material that when created with a 5% w/v ratio has been shown to have the same properties as acoustic foam but for underwater applications, which require higher compression resistance.

Phononic Glass

Smooth, dense material bounces sound waves as opposed to absorbing them. This layer of glass beads creates a network of surfaces that scatter and divide the larger sound waves, causing them to lose energy and weaken as they pass through.

"In order to achieve strong wide band acoustic absorption under high hydrostatic pressure, an interpenetrating network structure is introduced into the locally resonant phononic crystal to fabricate a type of phononic composite material called “phononic glass.” Underwater acoustic absorption coefficient measurements show that the material owns high underwater sound absorption coefficients over 0.9 in 12–30 kHz. Moreover, the quasi-static compressive behavior shows that the phononic glass has a compressive strength over 5 MPa which is crucial for underwater applications."

(Heng Jiang, Yuren Wang. 2012)

Air Cavities

Air chambers have been shown to significantly reduce the decibel levels of sound waves. They are currently used around oil rigs and underwater construction sites to mitigate noise pollution by the use of hoses which release a curtain of bubbles around the area. Our way to introduce this into the physical structure was including air pockets in the agar itself.

Sound Testing

We tested each material and design component individually for their acoustic properties between the 0 - 20,000 Hz range.

From our gathered data the cornered wall panels with an anechoic patch design provided the most effective sound resistance, with the materials adding additional protection in certain frequencies.

The goal is to create a string of barriers that run parallel to ship passageways, disrupting the noise pollution headed towards coastal areas.

Works Cited:

Heng Jiang, and Yuren Wang. “Phononic Glass: A Robust Acoustic-Absorption Material.” AIP Publishing, pubs.aip.org/asa/jasa/article/132/2/694/640399/Phononic-glass-A-robust-acoustic-absorption. Accessed 02 July 2025.